Our Products

Rubber Metal Bonded and Thermoplastic Engineering Products

Anti Vibrations, Dampers, Shock Absorbers

These products are intended to neutralize multi directional dynamic force bringing stability in curving & hunting motion, thereby reducing nose, wear and tear.

View Anti Vibrations

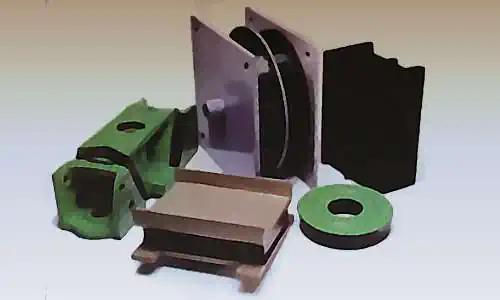

Bushings, Silent Blocks, Torsion Blocks

These links and bushings are mostly rubber-metal bonded products to control unintended torsion, conical and radial load bringing equilibrium to car body movement.

View Bushings

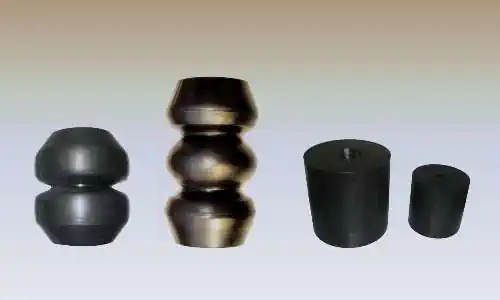

Rubber Springs and Hollow Rubber Bellows

Mostly hollow type all rubber products giving proper damping in the during car movement. Some are used in heavy vehicles and some in railway passenger coaches.

View Rubber Springs

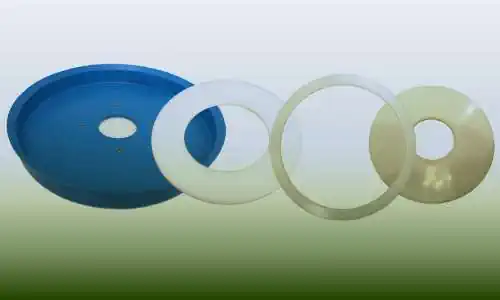

Thermoplastic Pads and Wear Plates

These pads prevent early damage of various rolling stock metallic parts due to high load bearing capacity, damping and wear resistance.

View TPE Pads

Electrical Insulation and Thermal Insulation

As the name suggests, these are all rubber products are used as highly reliable insulation covers where high voltage electricity passes through.

View Insulators

Gaskets, Rings, Seals, Rollers and Others

These are all tailor made moulded products manufactured with custom compounds depending upon end user's requirement. Metal bonded parts are also available.

View Gaskets