Research Paper

Electron Beam Radiation Technology for Vulcanisation

Introduction

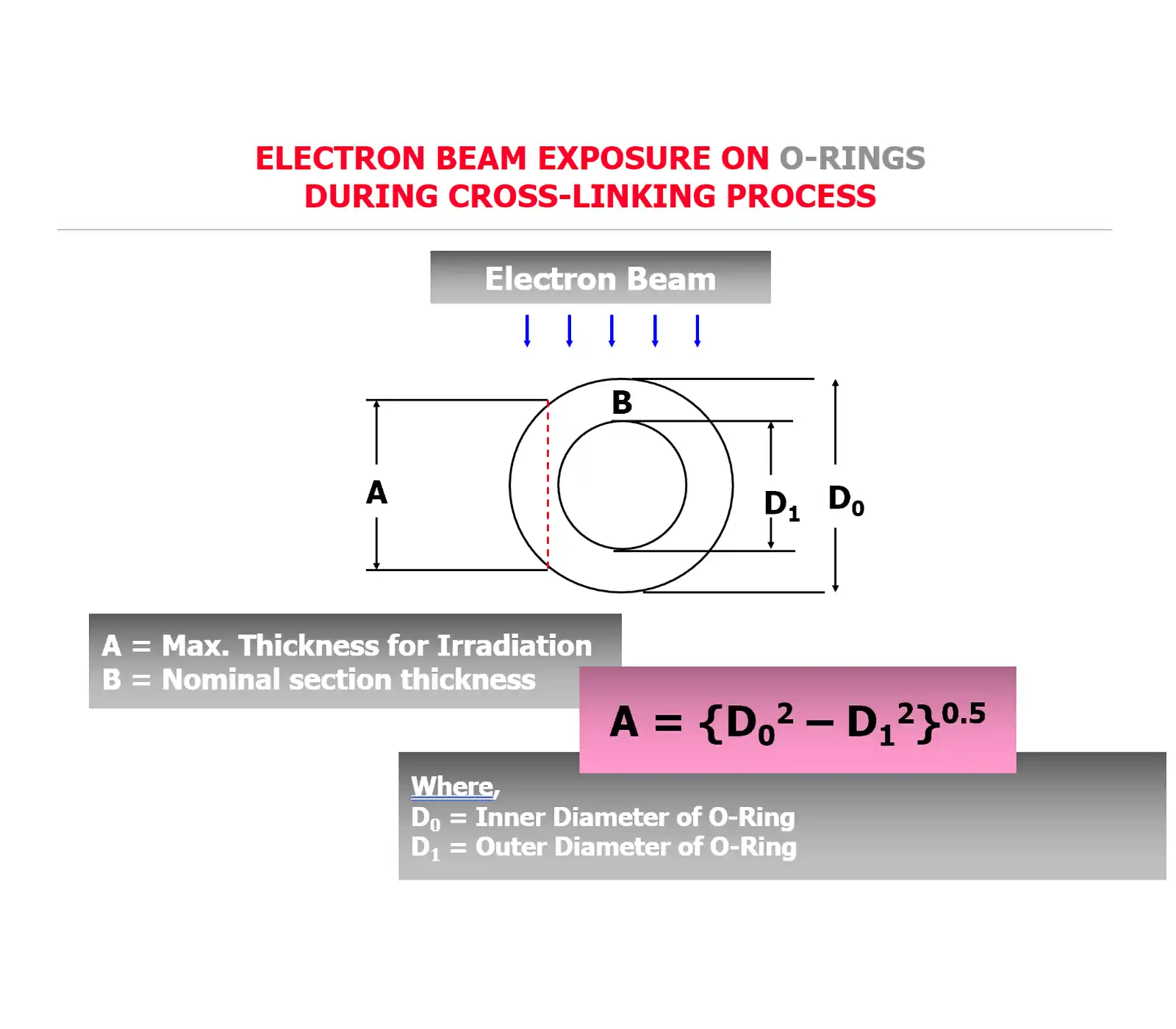

Cross linking of elastomer by electron beam irradiation technique is a new concept in the field of transport industry. Cables, Heat Shrink Tubes, PE Foams etc. are subjected to electron beam radiation with extreme advantages compared to other cross-linking systems. Cross linking of rubber compound for O Rings, Gaskets, Diaphragms, Seals revealed extremely positive results compared to any other Conventional or EV or Semi EV curing system. The effect and analysis of electron beam radiation of thin products such as O Rings, Gaskets and Diaphragms are discussed below.

Working Principle

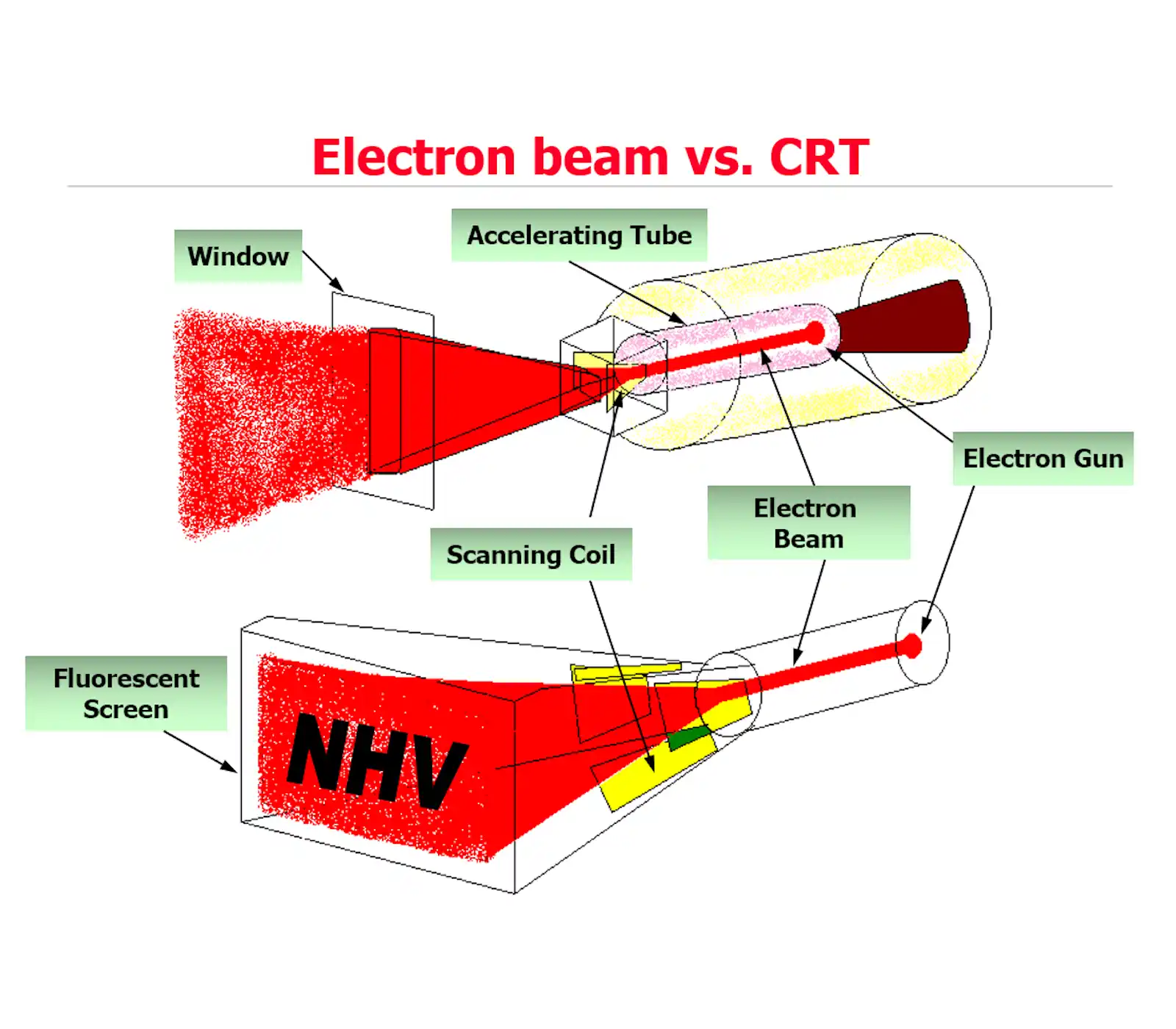

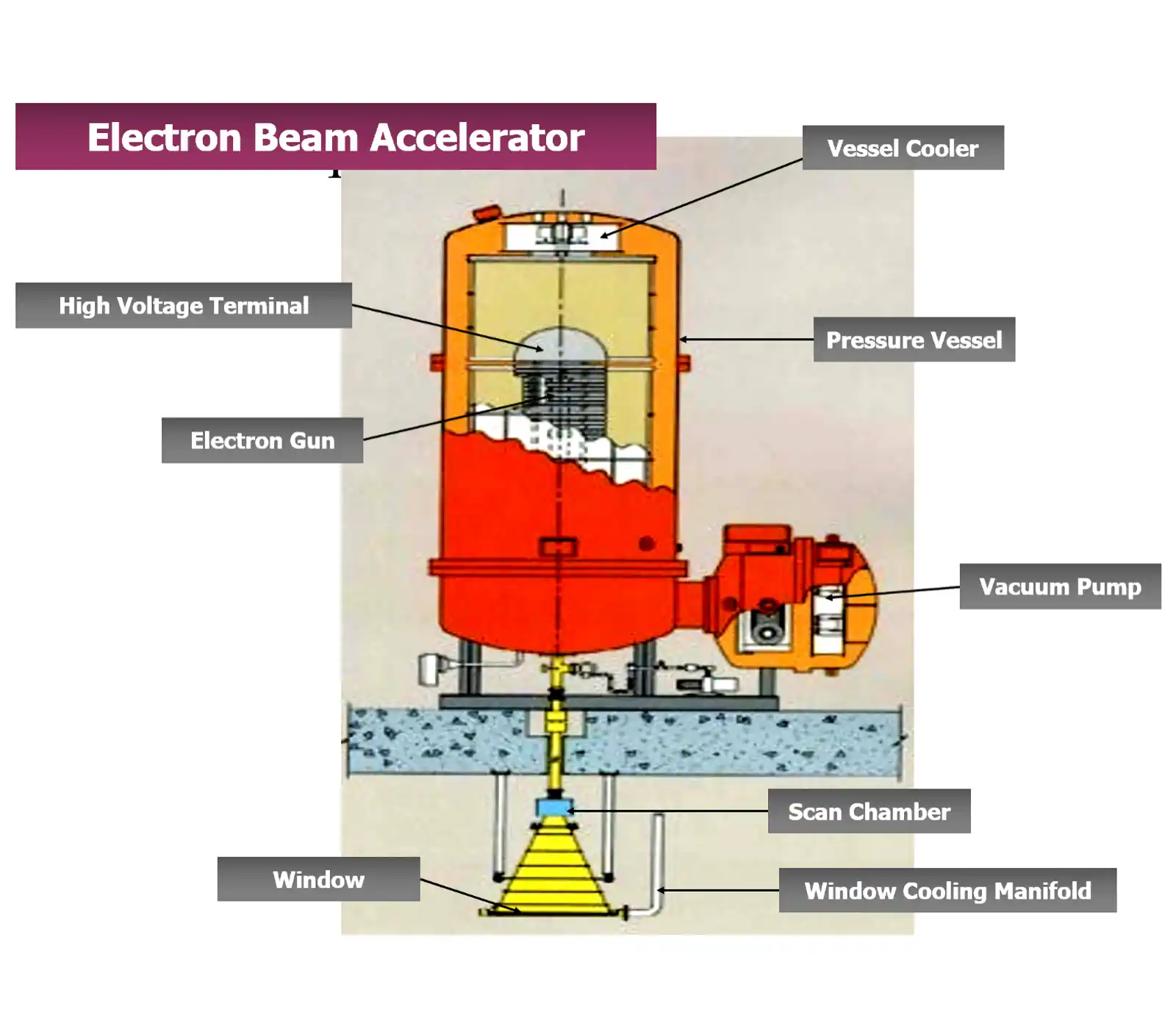

Basic principle is the same as a television. Accelerator work on the same principle as a television tube. Electrons are generated by a heated filament, which forms the electron gun. A voltage gradient draws the electron away from the gun and accelerates them through the vacuum tube. As the high voltage beam of electron passes from the beam tube and through the scan magnet, an oscillating magnetic field sweeps the beam back and forth across the scan window.

Technology Explained

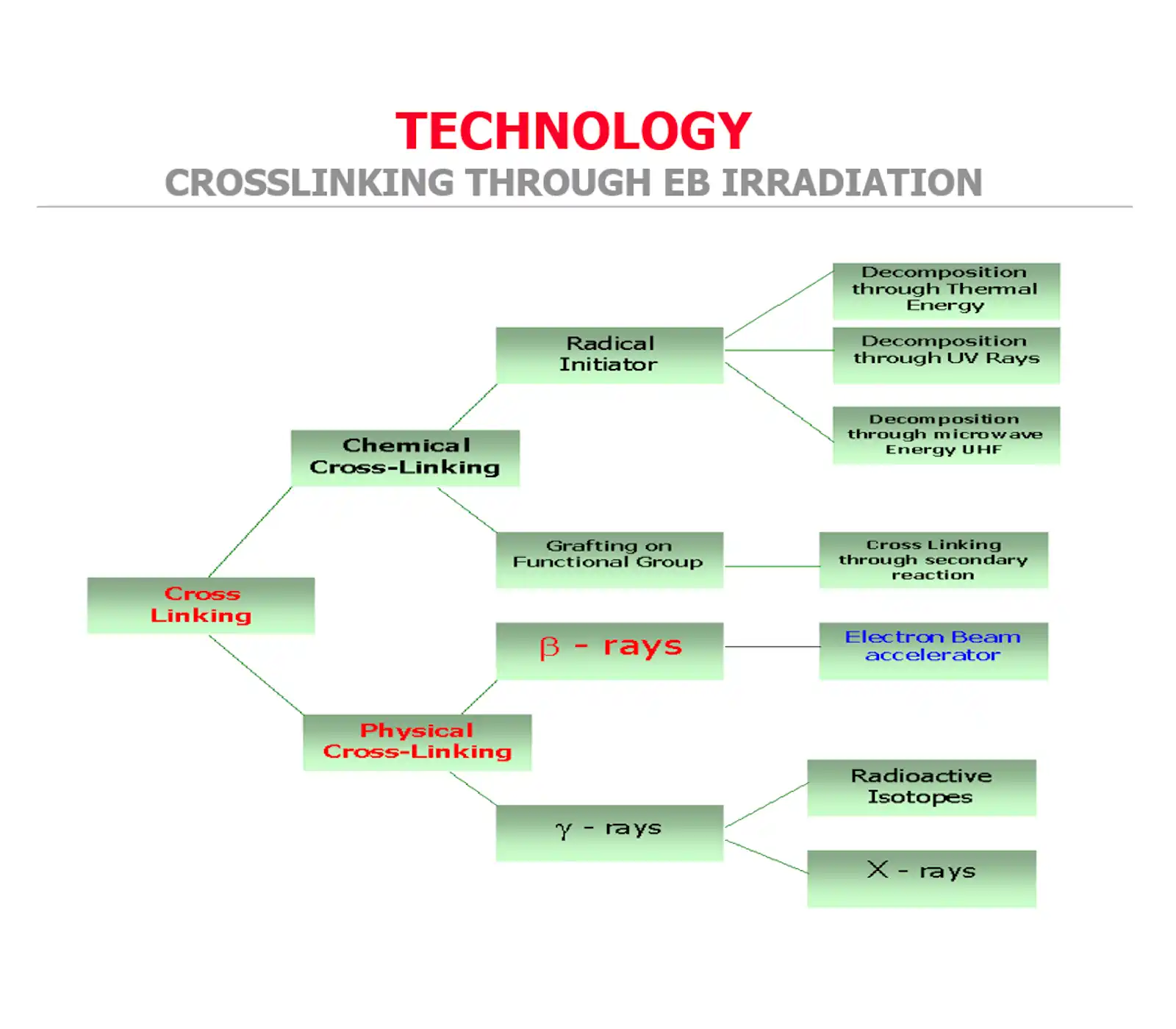

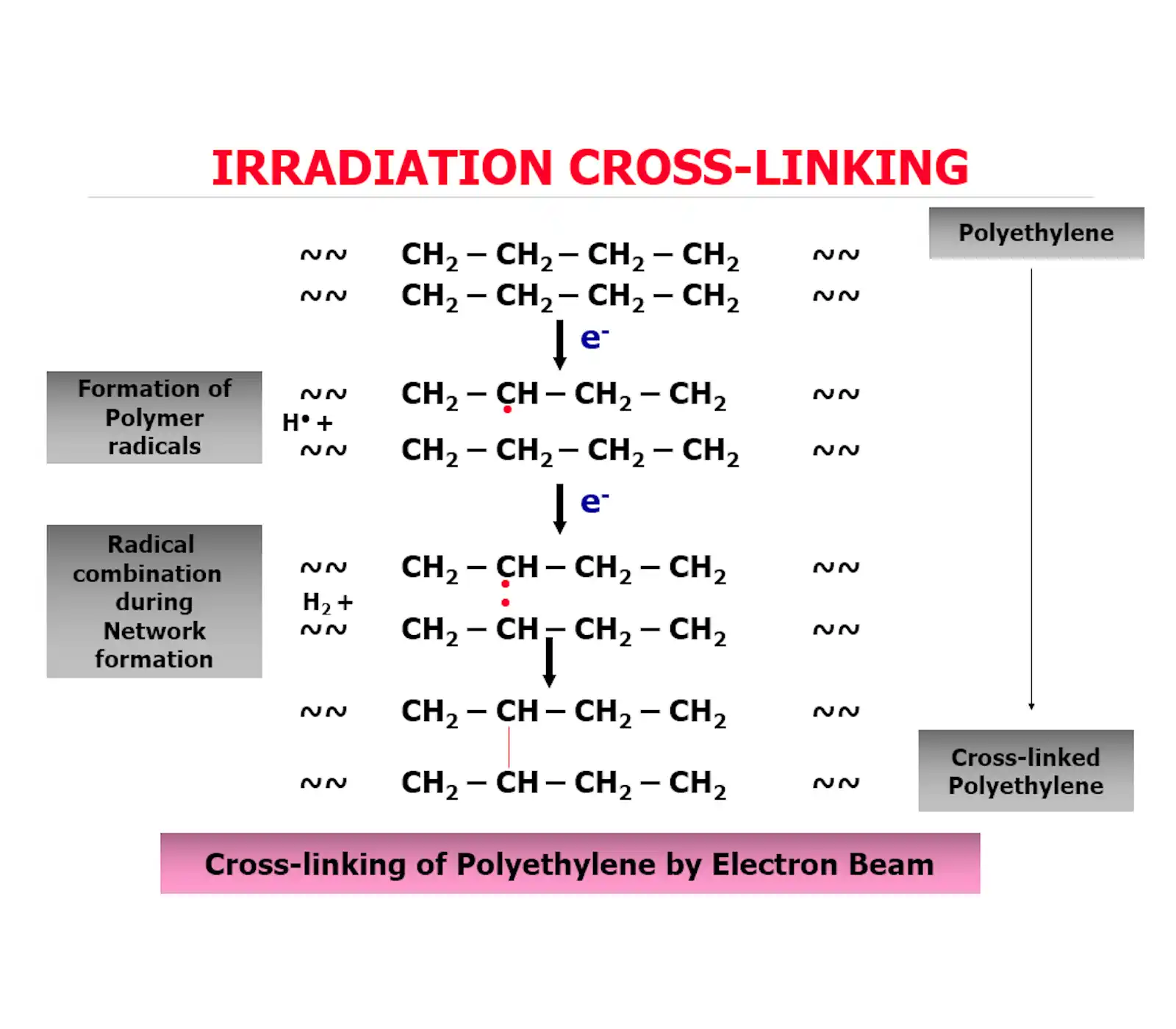

Vulcanization in the polymer chain or active cross linking inside the polymer matrix takes place through electron exchange influenced by electron beam irradiation. This type of cross linking is called physical cross linking. The process flow chart is given below for quick understanding.

Reason for Improvement

- High Degree of Cross Linking say between 75% to 85%.

- No polymer degradation due to high temperature as electron beam cross linking occurs at room temperature.

- No oxidative degradation in polymer as observed in chemical cross linking.

The Comparison Table

| # | E-Beam Radiation Curing System | Sulphur or Peroxide Curing System |

|---|---|---|

| 1 | Direct Cross-linking by C-C linkage by electron beams | Cross-linking by C-Sx–C linkage (x= 1,2,3...) or C–Ox–C linkage (x=1,2,3 ...) |

| 2 | Extremely Strong Bonds | Comparatively weaker bonds |

| 3 | Zero blooming effects | Sulphur/Oxide have chance to bloom to periphery leading to surface deterioration |

| 4 | Extremely High Tensile Strength | Comparatively Lower Tensile Strength |

| 5 | Extremely high resistance to Compression Set | Lower resistance to Compression Set |

| 6 | Extremely high resistance to Oils, Grease, Lubricants | Lower resistance to Oils, Grease, Lubricants |

| 7 | Highly improved Accelerated Ageing properties | Lower accelerated ageing properties compared to E-Beam system. |

| 8 | Lower material waste | Higher Material Waste | 9 | Extremely short curing cycles | Comparatively curing time is quite high | 10 | Very high productivity | Comparatively Lower productivity | 11 | Perfect for thin products | Good for bigger products |

Test Results of Electron Beam Irradiated Rubber Gaskets, O Rings and Diaphragms

The following table contains data obtained from various vulcanized acrylonitrile rubber-based product like O Rings, Gaskets and Diaphragms.

This is a comparative study between sulfur accelerator vulcanization and electron beam radiation vulcanization of acrylonitrile rubber-based

products.

| Physical Properties | Sh 60°±5°A | Sh 70°±5°A | Sh 80°±5°A | |||

|---|---|---|---|---|---|---|

| Hardness in Shore A | 58 | 63 | 70 | 72 | 80 | 84 |

| Tensile Strength, MPa (min) | 9.5 | 13.0 | 13.2 | 15.0 | 12.5 | 14.0 |

| Elongation at Break, % (min) | 340 | 280 | 390 | 300 | 210 | 180 |

| Compression Set at 25% deflection at 100°C for 24 Hours | 10.1 | 2.6 | 9.1 | 2.5 | 22.5 | 2.2 |

| Swelling in Fuel B at room temperature for 24 hours, volume change, % (max) | 27.5 | 22.0 | 24.5 | 22.0 | 22.5 | 21.0 |

| Swelling in Lubricating Oil (Servo System 57 of IOC or equivalent) at 100°C for 72 hours, volume change, % (max) | -6.2 | -0.1 | -4.1 | 1.0 | -4.0 | -2.0 |

| Swelling in lithium-based grease at 100°C for 72 hours, volume change, % (max) | -6.2 | -1.5 | -5.5 | -1.5 | -4.0 | -2.0 |

| Change in ultimate tensile strength carried out on a product which has undergone accelerated heat ageing at air oven at 100°C for 72 hours, % (max) | -12.0 | +9.0 | -9.2 | +10.0 | -13.0 | +10.0 |

| Change in Shore °A Hardness after accelerated ageing conducted in air oven at 100°C for 72 hours, % (max) | +5 | +4 | +5 | +4 | +6 | +1 |

| Sulfur | Electron | Sulfur | Electron | Sulfur | Electron | |

Conclusion

Use of electron beam radiation technology for vulcanization of thin rubber products definitely exhibit much superior properties compared to common methods of chemical cross-linking involving heat and pressure. The upgraded physical properties reflect in application and enhance the usability as well as service life of the thin rubber product.

Publishing Footnote

After meticulously conducting research and analyzing the data gathered, the final conclusion of our study underscores the importance of publishing

our research article to the public domain. Our findings have significant implications for both academia and society at large, shedding light on

previously unexplored facets of the subject matter. By making our research freely accessible to all, we aim to foster transparency, facilitate

further inquiry, and contribute to the advancement of knowledge in our field. Moreover, sharing our findings with the public enables broader

engagement and dissemination of valuable insights, potentially influencing policy decisions and practical applications. Thus, we are committed

to publishing our research article to the public domain, ensuring its accessibility and impact for the betterment of our collective understanding

and progress.

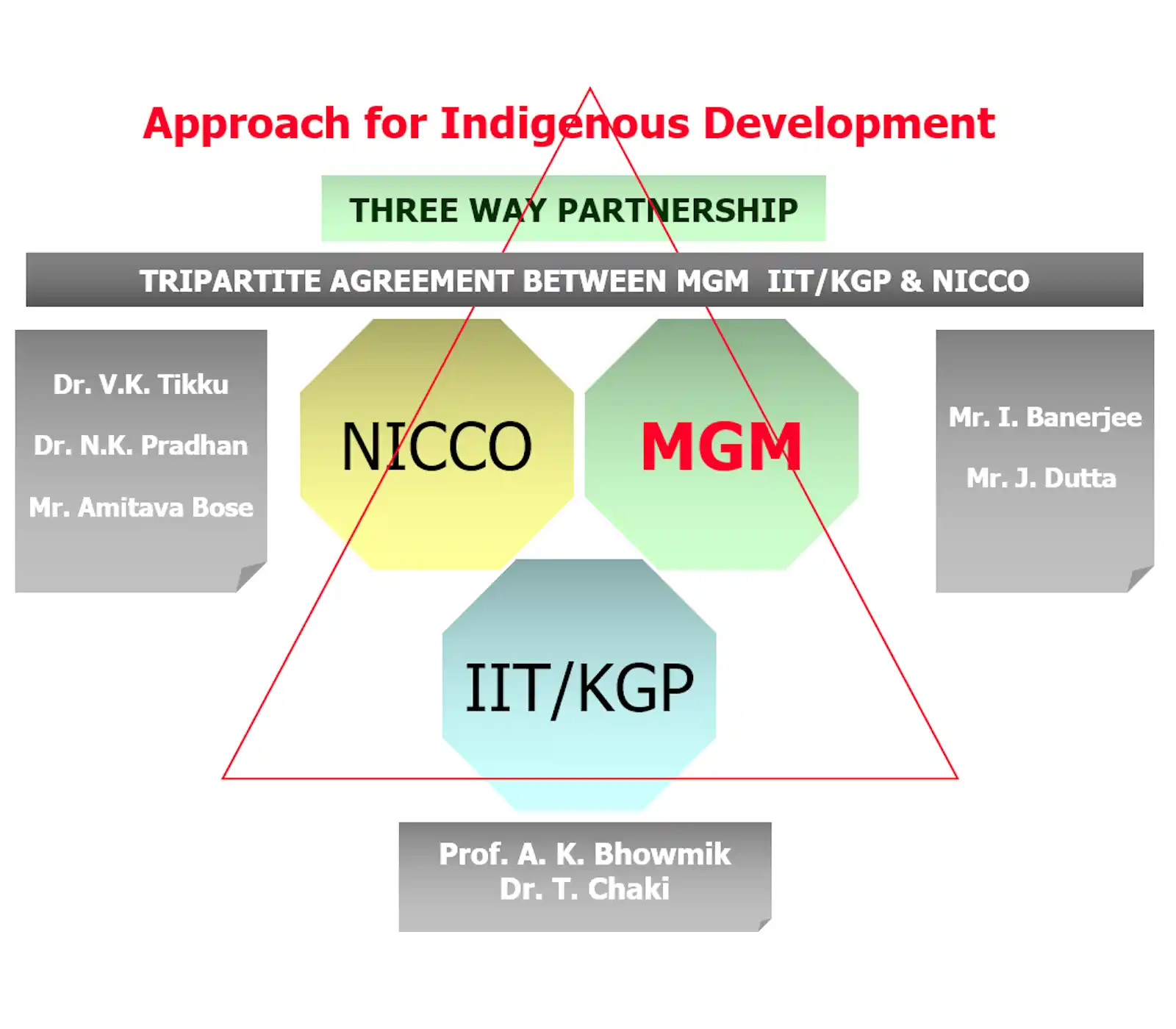

Published By : Research and Development Wing of M.G.M. Rubber Company, Kolkata, India

Published On : November 2003