Research Paper

Protecting Helical Coil Spring using Thin Thermoplastic Pads

Introduction - Recent Advancements in Thermoplastic Spring Pads for Railway Suspension Systems

Thermoplastic spring pads have become essential components in modern railway suspension systems, particularly in locomotives and passenger coaches. Positioned above and below the helical coil springs, these pads play a critical role in enhancing the service life of coil springs by minimizing fretting and offering superior damping characteristics.

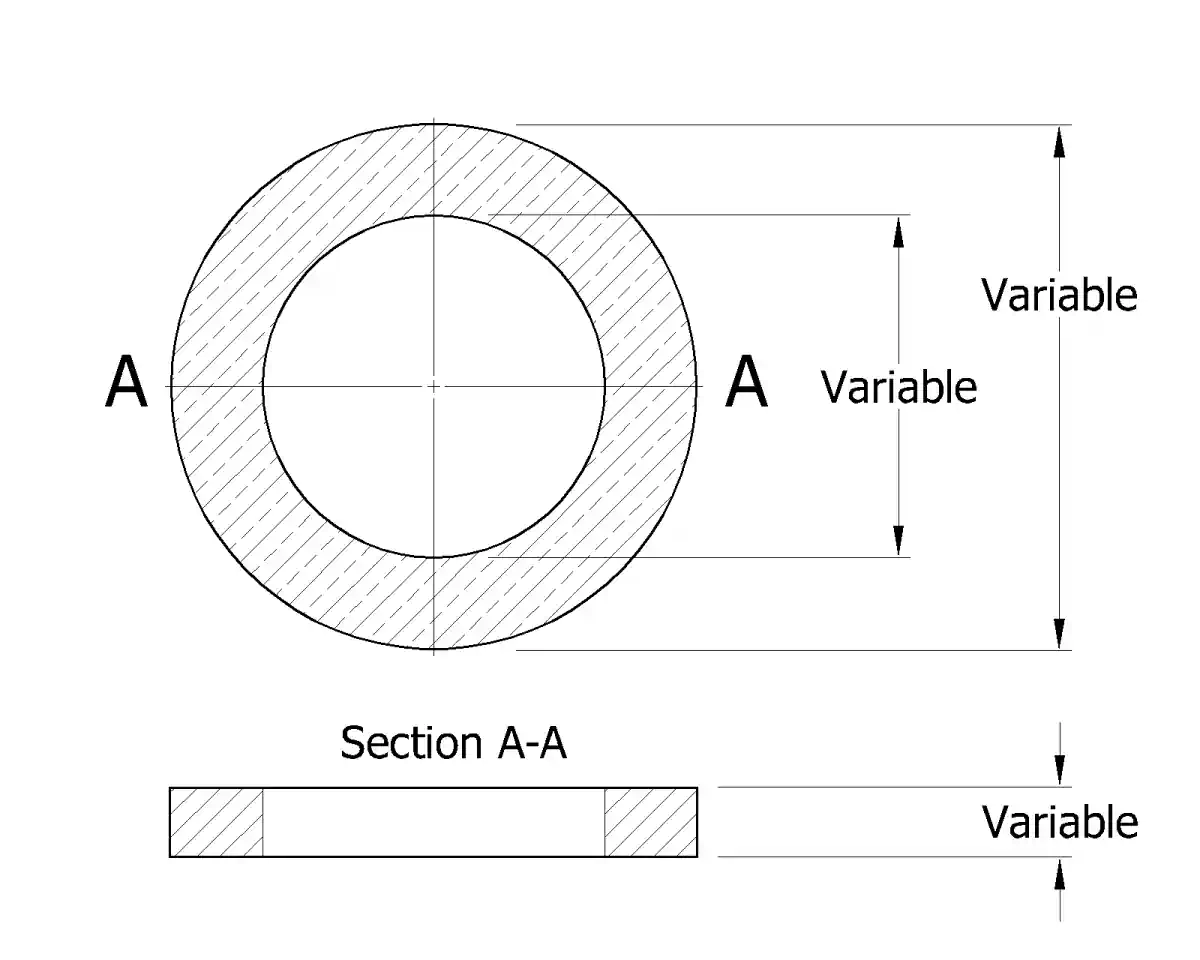

A newly developed version of these ring-shaped thermoplastic spring pads, which is approximately 40% thinner yet significantly more advanced in the service performance has been implemented in FIAT bogies used by Indian Railways. This innovation aims to improve cushioning, optimize suspension dynamics, and extend the operational lifespan of coaching stock.

These pads effectively absorb shocks and attenuate vibrations, thereby improving riding characteristics and minimizing wear and tear on suspension components. By evenly distributing loads across the coil springs, these pads help to prevent localized stress concentrations and mitigate the risk of premature coil spring failure. Additionally, these specially compounded thermoplastic spring pads are known for their high resistance to abrasion, chemicals, and environmental degradation, further contributing to the durability and reliability of railway suspension systems.

Environment and Service Condition

The Thermoplastic Rings are used very widely under severe weather conditions. The limiting conditions, which must be withstood in service, are indicated below:

- Maximum Working Temperature: +70°C

- Minimum Working Temperature: -40°C

- Maximum Temperature attainable by an object exposed to sun (current carrying object): 100°C

- Maximum Relative humidity: 100%

- Average Annual Rainfall: 1750mm to 6250mm

- Maximum Wind Pressure: 200 Kg/Sq. Meter

- Altitude: Up to 3000m

Encountered Displacement of Coach Body under dynamic conditions:

- Vertically: ±55 mm

- Laterally: ±100 mm

- Longitudinally: ±10 mm

- Bogie rotation about Center Pivot: ±40

- Maximum Speed of Train: 200 KMPH

Mechanical and Functional Implications of Reduced-Thickness Thermoplastic Pads

In conventional railway application, the thermoplastic spring pads are employed in locomotive bogies at a thickness of about 10mm. This has ensured adequate performance because the dynamic loads on the suspension of locomotives are not very severe. However, this type of pad cannot be accommodated within the design and spatial constraints of passenger coach bogies, particularly FIAT bogies in LHB Coaches. Therefore, to meet these dimensional restrictions, it has been made possible to provide thinner thermoplastic spring pads of about 6mm thickness without compromising assembly integrity.

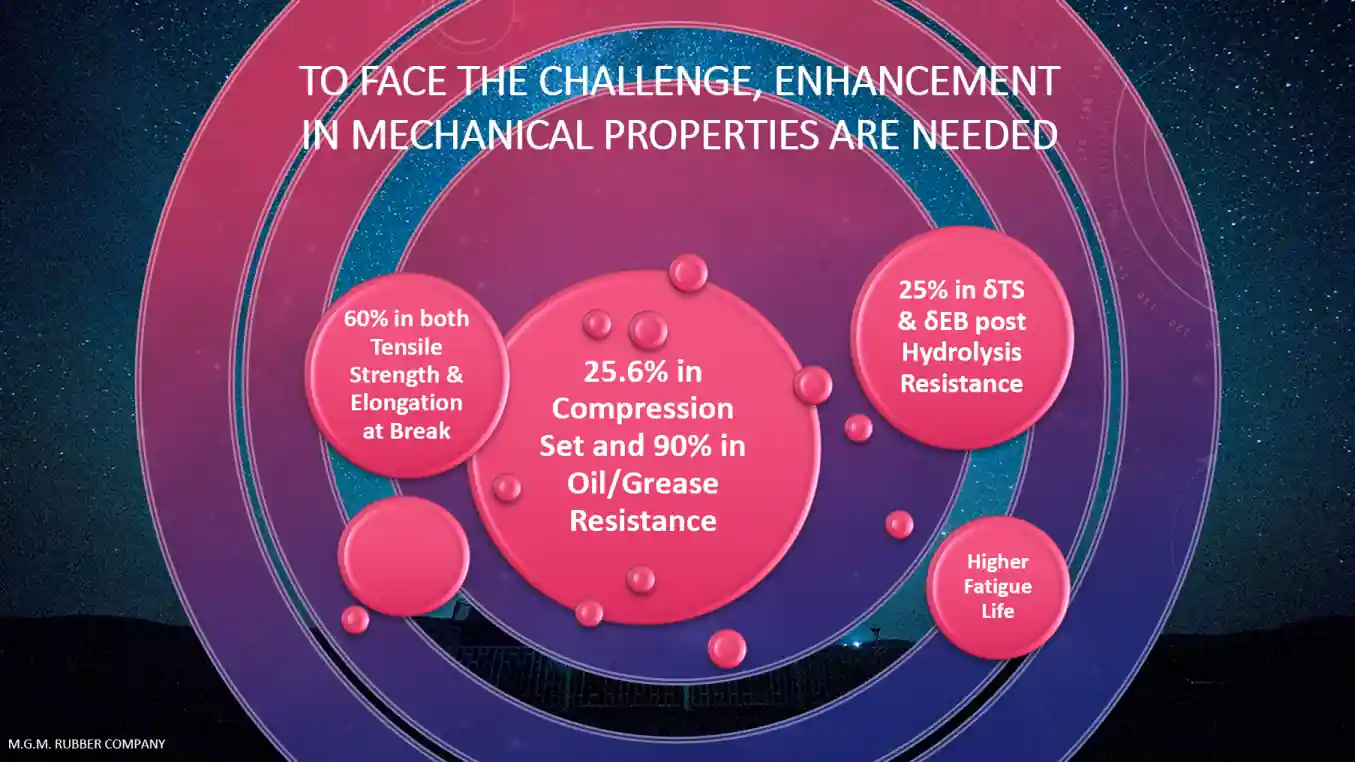

Despite resolving the space problem, the application of these thinner pads in passenger coaches introduces new challenges due to the significantly higher operational loads involved during dynamic application condition. In practice, the spring pads in passenger coaches are subjected to application loads that are approximately 80% higher than those typically encountered in locomotives. When the challenge of a 40% reduction in thickness is coupled with an 80% increase in operational load, the resultant stress per unit volume increases abruptly. This elevated stress accelerates the degradation of the mechanical properties of the pad over time, particularly mechanical properties like elasticity, energy absorption, and damping behavior are affected.

Over time, these over stressed pads tends to undergo permanent set during continuous dynamic fatigue and hysteresis heat build-up, leading to a abrupt increase in material stiffness. This progressive stiffening significantly affects the pad’s ability to perform its primary function of protecting the helical coil springs from fretting damage, stress concentration, and premature failure. Whenever the pad loses its elasticity and damping ability, the coil springs become increasingly exposed to dynamic load. This reduces the effectiveness of the entire suspension system which in turn adversely affect ride comfort, component longevity, and safety margins.

Although the 40% reduction in thickness of thermoplastic spring pads solves the space constraints of Indian Railway passenger coaches but their performance in long term specially under elevated dynamic loading conditions remains a matter of great concern. This raises the demand for further optimization in compound formulation, optimization of geometry, and thermo-mechanical re-design and thereby ensuring reliable performance over the entire service life of railway suspension systems.

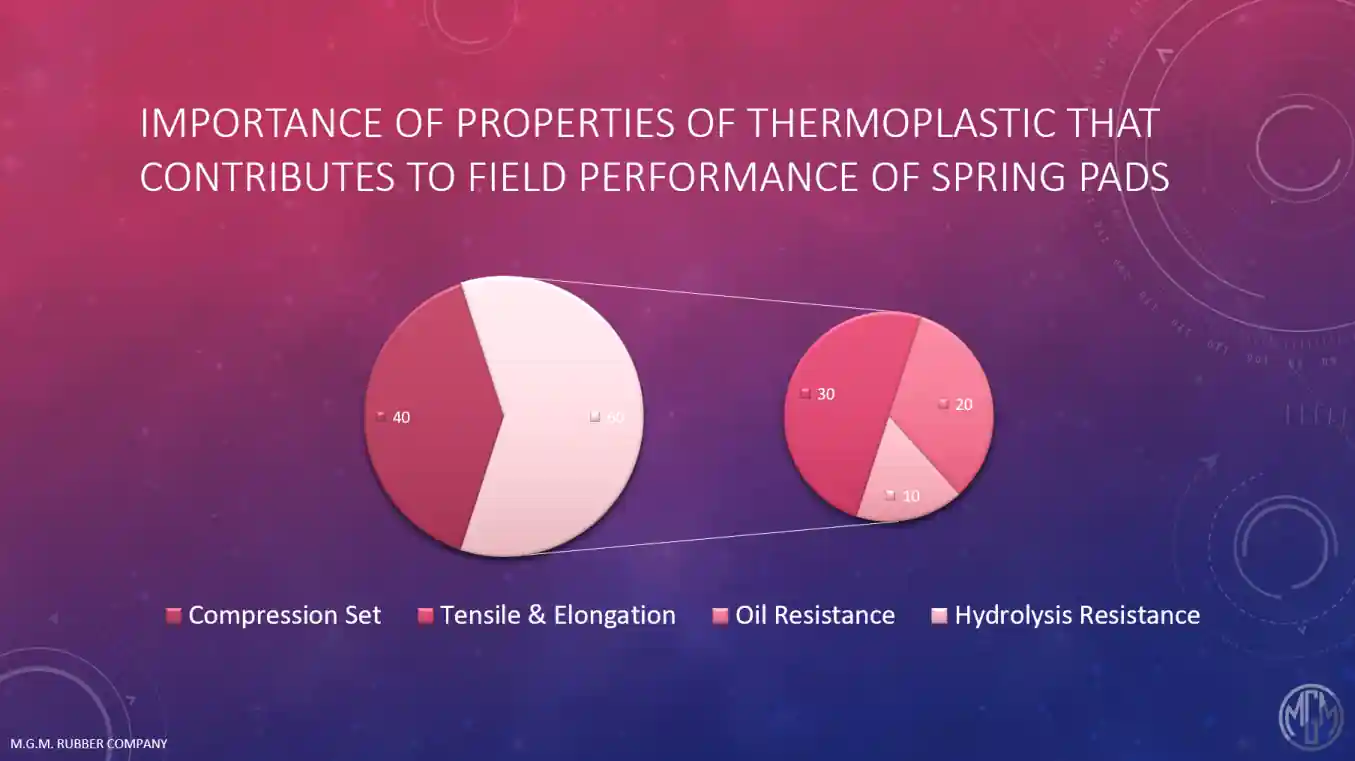

Mechanical Properties which play a Crucial Role

Compression Set

It is important to note that lower compression set value helps the pad to avoid deep groove formation on its surface, effectively retaining critical thickness of product and damping characteristics.Oil Resistance

Excellent Oil Resistance Property contributes to volume swelling resistance, effectively retaining its structural stability, hardness and shock absorbing ability.Resistance to Hydrolysis

Improved Resistance to Hydrolysis helps the product in retaining its core mechanical properties like tensile strength, elongation at break and hardness.Tensile Strength, Elongation at Break

Higher Tensile Strength and Matching Elongation at Break will help the pad in retaining minimum level of operational strength required for a longer duration of time.

Quantifying the Necessary Improvement

The Upgraded Properties and Comparison Table

| Property | Old | Upgraded |

|---|---|---|

| Tensile Strength (ASTM D638 / ISO 527) | 250 kg/cm² (min) | 400 kg/cm² (min) |

| Elongation at Break (ASTM D638 / ISO 527-1 & ISO 527-3) | 300% (min) | 480% (min) |

| Compression Set at 80°C ± 1°C for 24 Hrs. (ISO 815) | 45% (max) | 30% (max) |

| Oil Resistance in Lubrex-150 or HLP-68 for 72 (+0, -2) Hrs. at 100°±1°C (IS 3400 Pt. VI) | 20% (max) | 1.5% (max) |

| Oil Resistance in Grease (Servogem 2 or 3) for 72 (+0, -2) Hrs. at 100°±1°C (IS 3400 Pt. VI) | 15% (max) | 1.5% (max) |

|

Change in Tensile Strength (ẟTS), Elongation at Break (ẟEB) and Shore A Hardness (ẟSH) after Hydrolysis for 72 (+0, -2) Hrs. in boiling water. Must satisfy any one of the following options: [Option-1]

|

|

[Option-1]

|

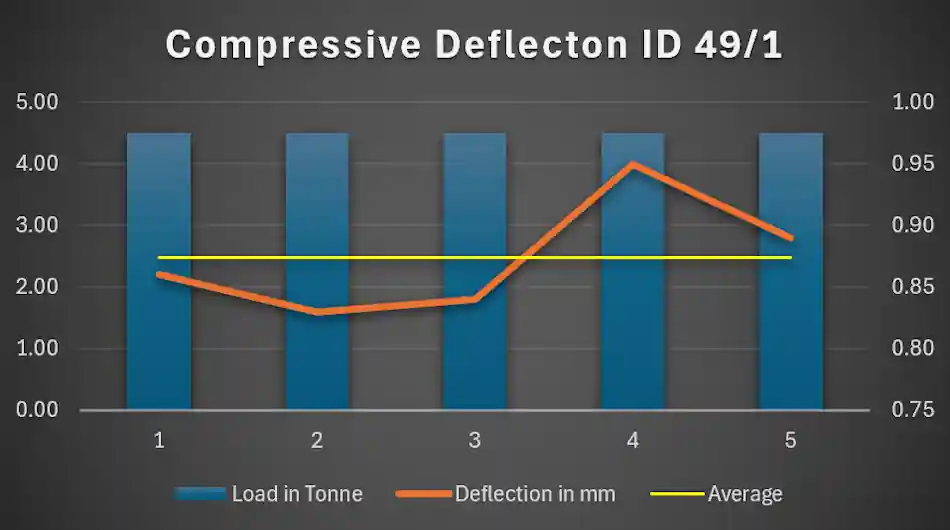

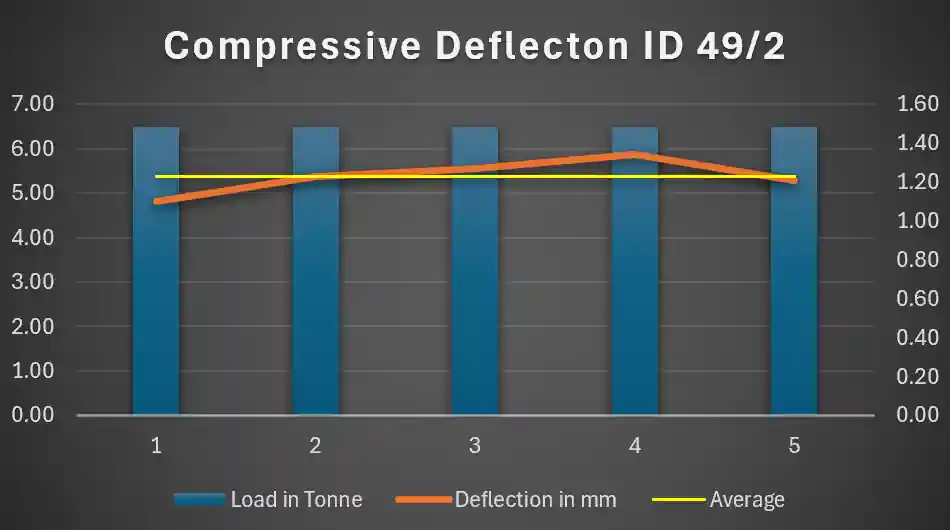

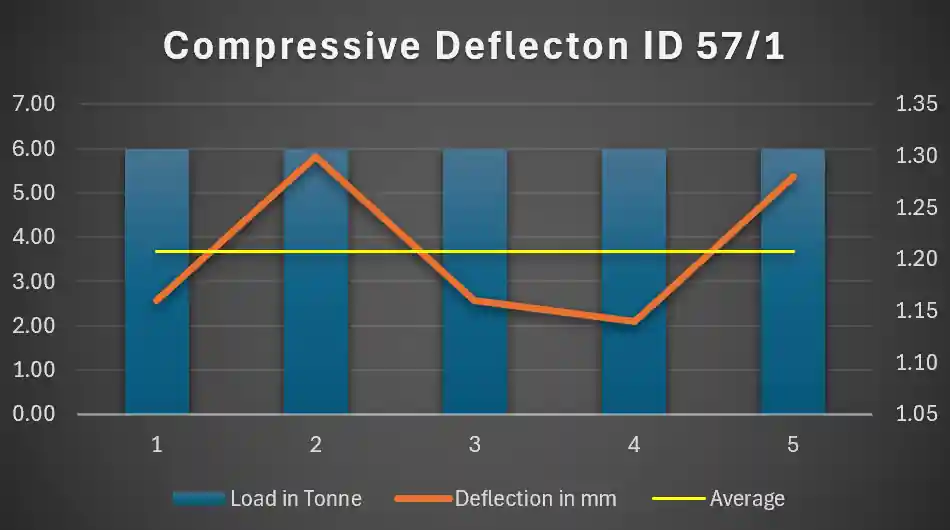

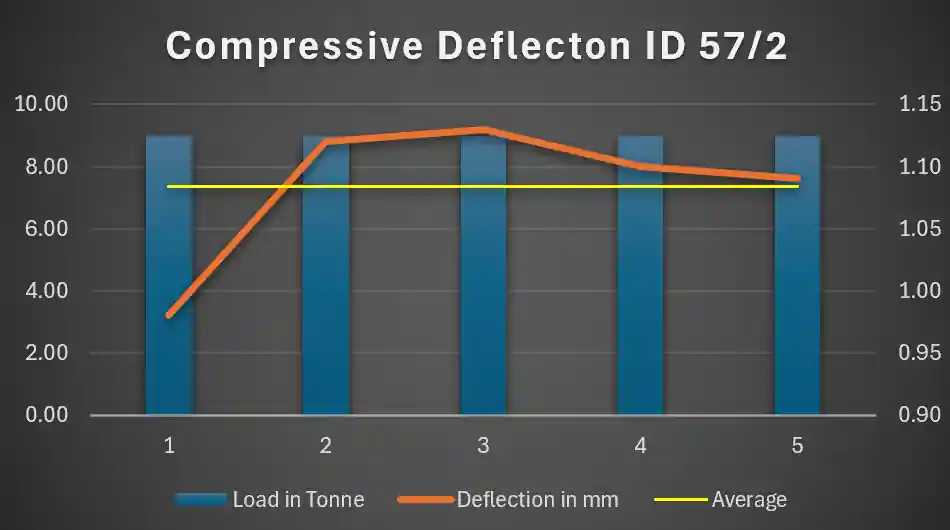

Compressive Load Deflection Result

Conclusion

To meet this demanding mechanical and environmental requirements of 40% thinner thermoplastic spring pads used in 80% higher dynamic applications, the base polymer was specially compounded using some advanced additives. These additives were selected to enhance some mechanical properties of base resin for example impact resistance, elasticity retention, fatigue strength, chemical stability, resistance to thermal and oxidative degradation and so on. The resulted in maintaining its mechanical properties under elevated stress and in even more contaminated service environments.

Prior to injection moulding, the specially compounded thermoplastic material went for a critical drying process using a dehumidifying type dryer. The dew point maintained therein is below -40°C. This ensured the removal of residual moisture that could otherwise compromise moulding quality and result in microstructural defects or reduced mechanical performance. Post moulding, the spring pads were subjected to a controlled annealing process at 100 °C for a duration of 16 hours. This thermal treatment relieved internal stresses induced during moulding and enhanced the dimensional stability and mechanical properties of the final product.

The output has finally demonstrated a reliable performance under a harsher and even more contaminated environmental condition and not only ensured ease of fitment but also displayed sustained performance in the real world.

Publishing Footnote

After meticulously conducting research and analyzing the data gathered, the conclusion of our study underscores the importance of publishing our research article to the public domain. Our findings have significant implications for both academia and society at large, shedding light on previously unexplored facets of the subject matter. By making our research freely accessible to all, we aim to foster transparency, facilitate further inquiry, and contribute to the advancement of knowledge in our field. Moreover, sharing our findings with the public enables broader engagement and dissemination of valuable insights, potentially influencing policy decisions and practical applications. Thus, we are committed to publishing our research article to the public domain, ensuring its accessibility and impact for the betterment of our collective understanding and progress.

Published By : Research and Development Wing of M.G.M. Rubber Company, Kolkata, India

Published On : December 2024